Metal Clad Doors

Metal clad doors are suited to commercial and industrial conditions where the door leaf requires significant protection against damage. Metal cladding also acts as a protectant against the elements in order to fulfil sheltered outdoor applications.

Optionality in metal material, thickness, and covering provides the ability to build the appropriate door for your application whilst fitting into project scope and budget.

Fire Door Fitting

Metal cladding is suited to Spence’s Fire Doors with a series of fire-rated door set configurations tested and certified with metal cladding. The metal surface also hosts non-combustible properties to increase the door’s heat threshold to ignite.

Hygienic

Metal facings have the added benefit of a uniform and easy-to-clean surface. Metal does not host live germs for the same period as standard door skins. This is an advantage for settings where hygiene is imperative like hospital / healthcare or building with quarantined compartments like airports.

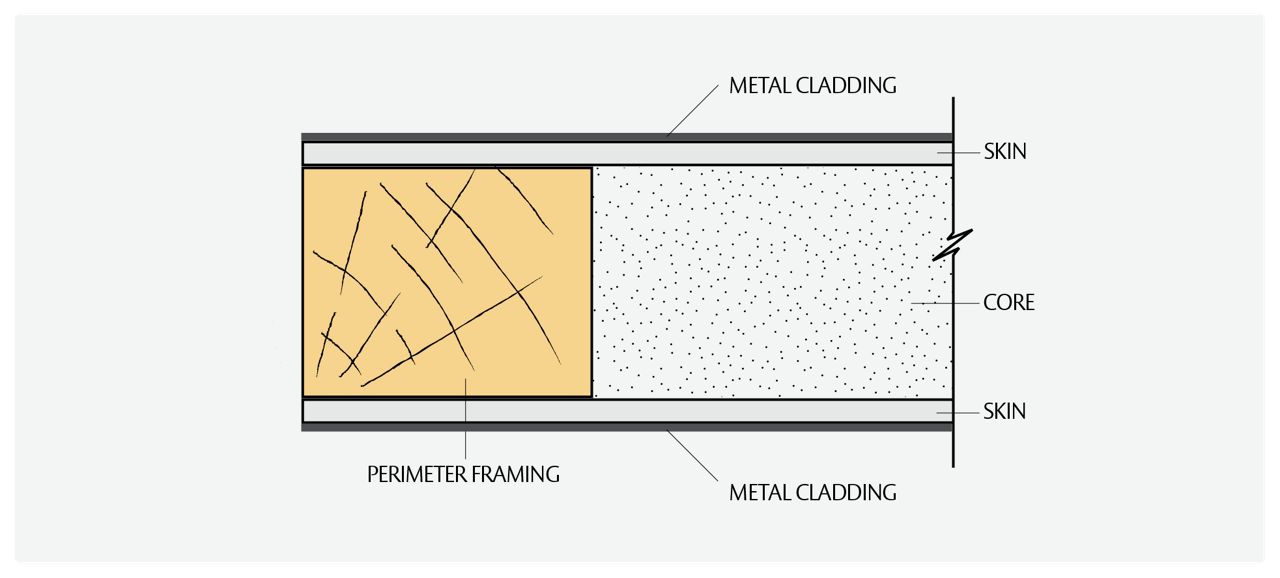

Metal Faced Door

A metal sheet applied from edge-to-edge on the door face(s).1 of 3

Damage Resistant

Strong materials engineered to hold against direct impact and wear-and-tear.

Easy Clean

Surface is made for easy cleaning in environments with high hygiene standards.

Options

A wide selection of options are available to accommodate specific needs.

Specifications

The dimensional properties and material composition of Spence's metal cladded door range.

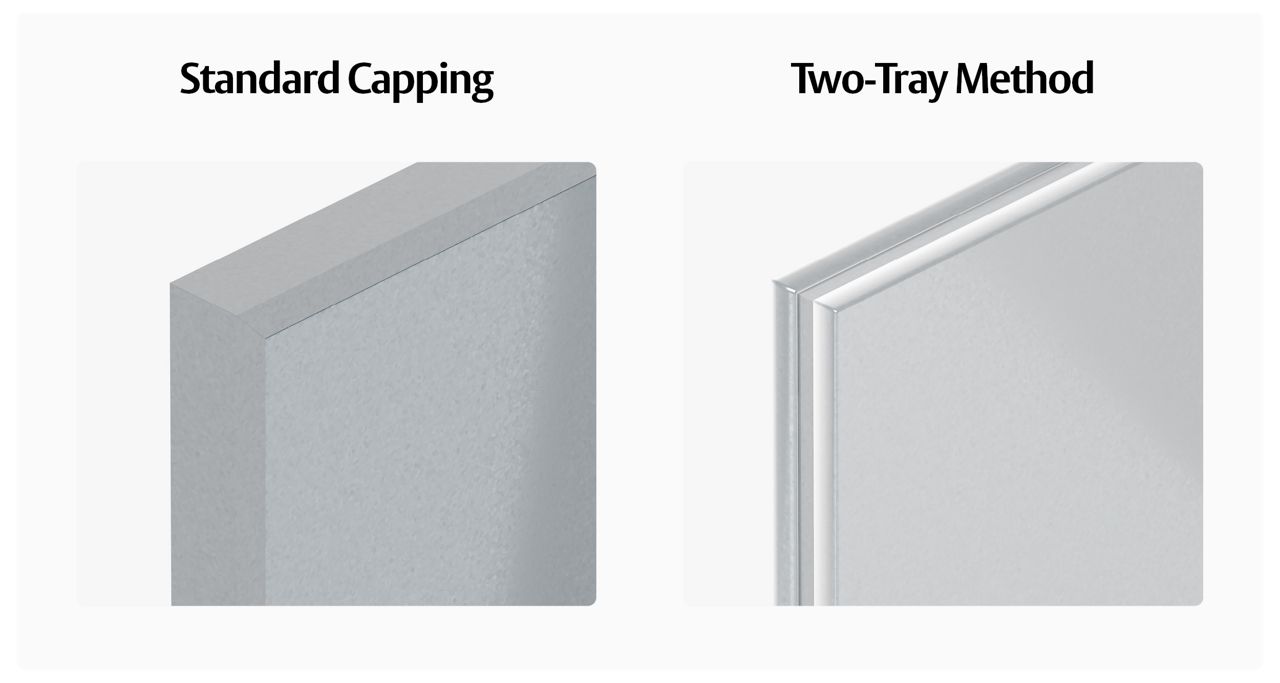

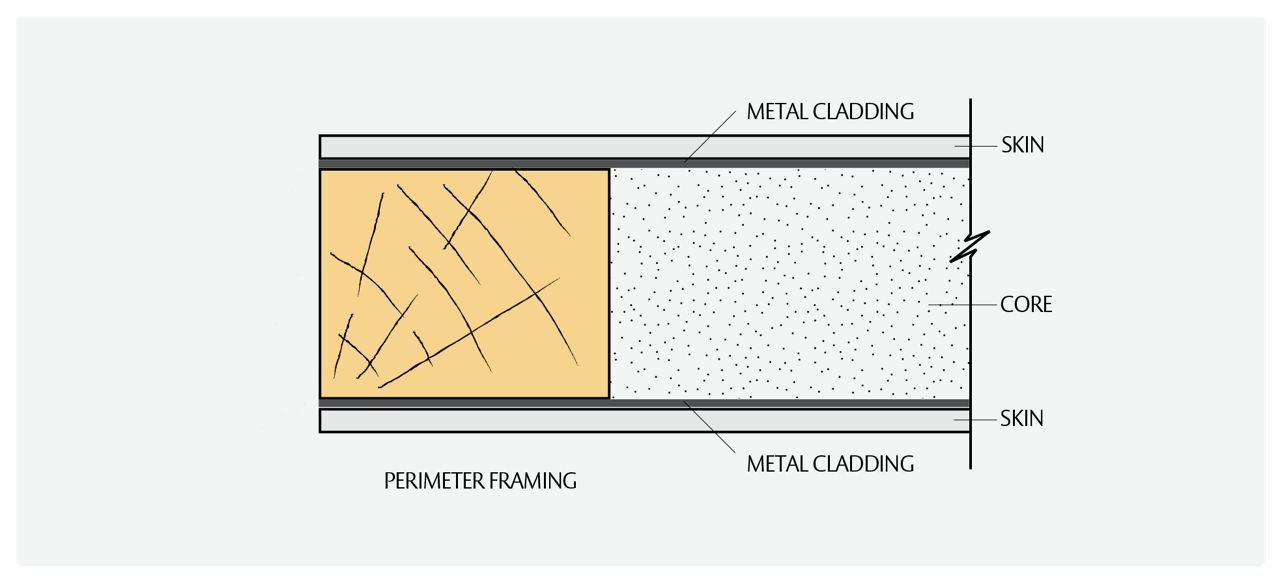

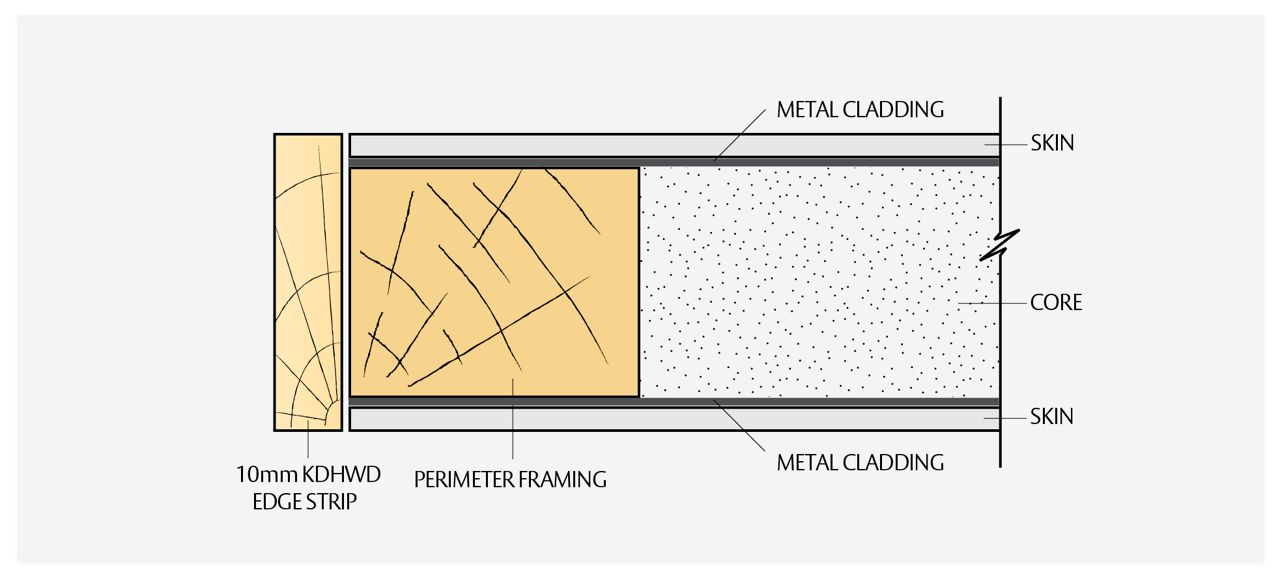

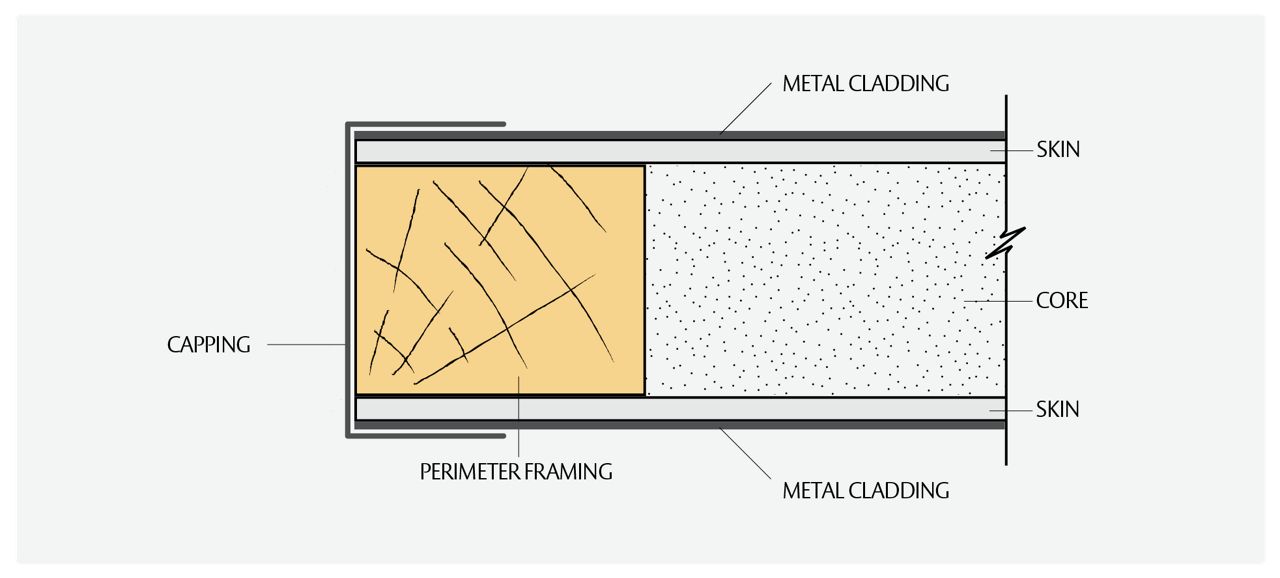

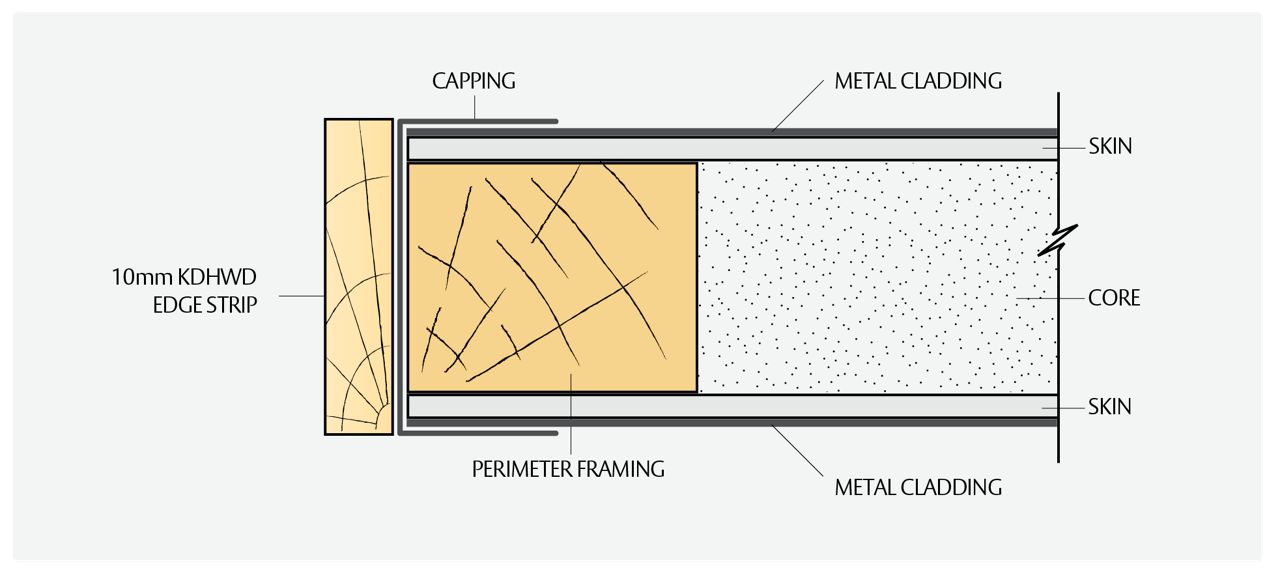

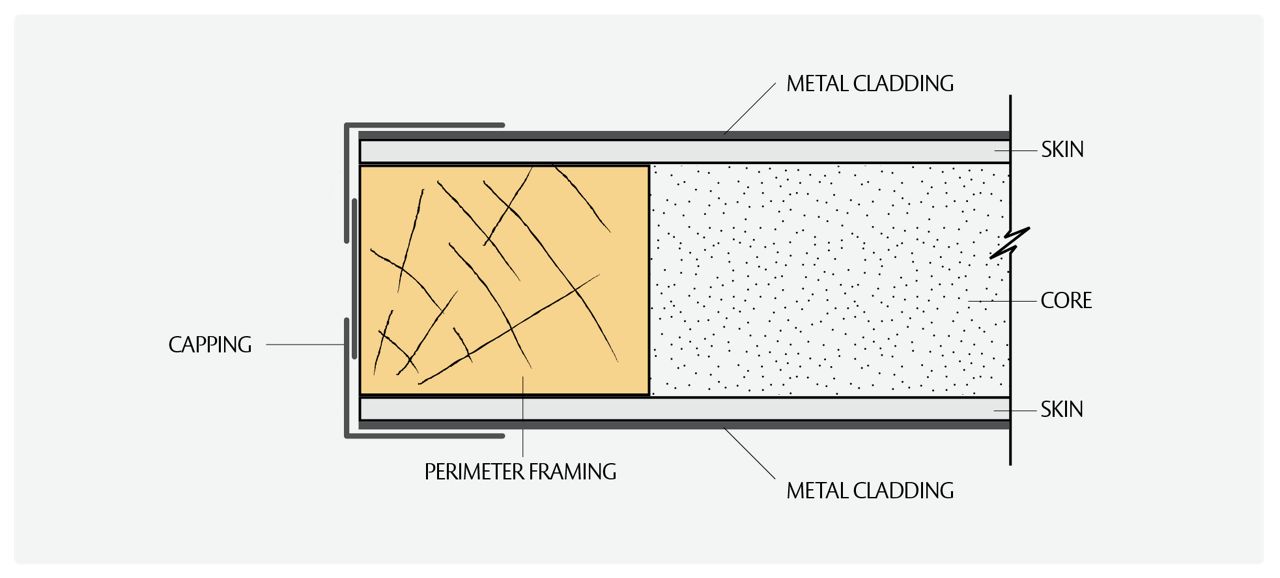

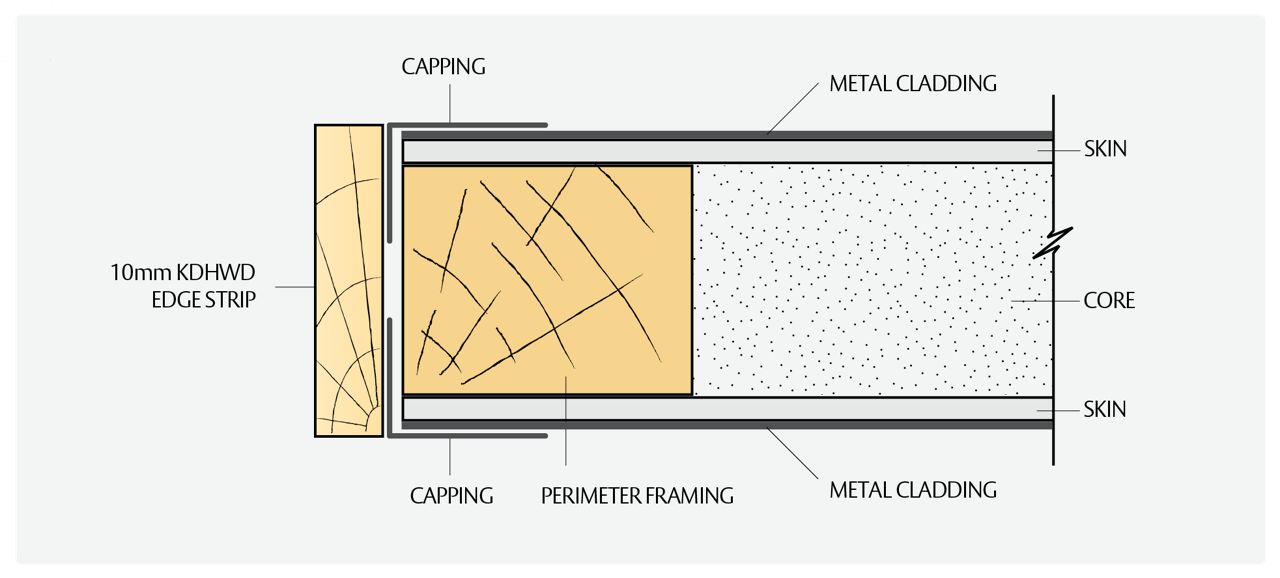

Configurations

The variations of metal capping to accommodate the extent of protection the door requires.

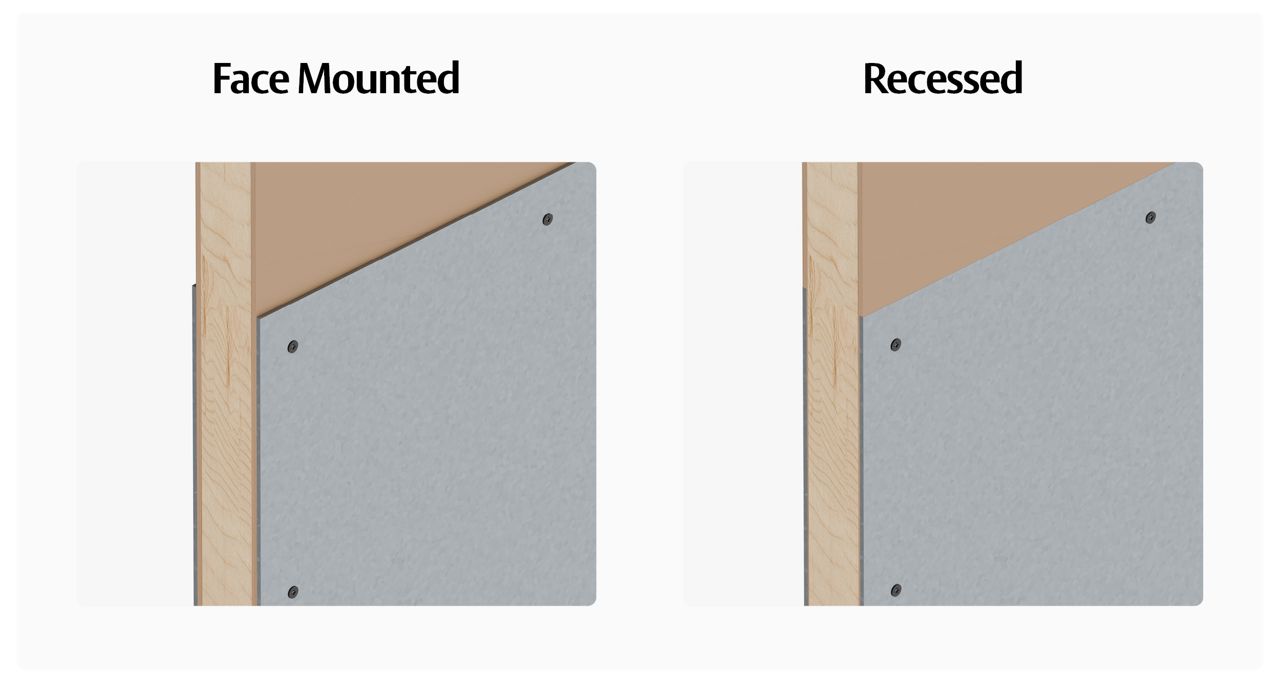

Installation

The technical detail of each variation's installation.

Compatability

How metal cladding can service purpose-built door sets for the likes of Fire and Acoustic doors.

Extras

Vision Panel

A window fitted to the door face for visibility between rooms. Options available for glass finish and thickness.

Ventilation Grille

A grille fitted into the door's face to allow for airflow between rooms. This is a support of a building's HVAC systems, ensuring appropriate airflow and minimising air conditioning costs.

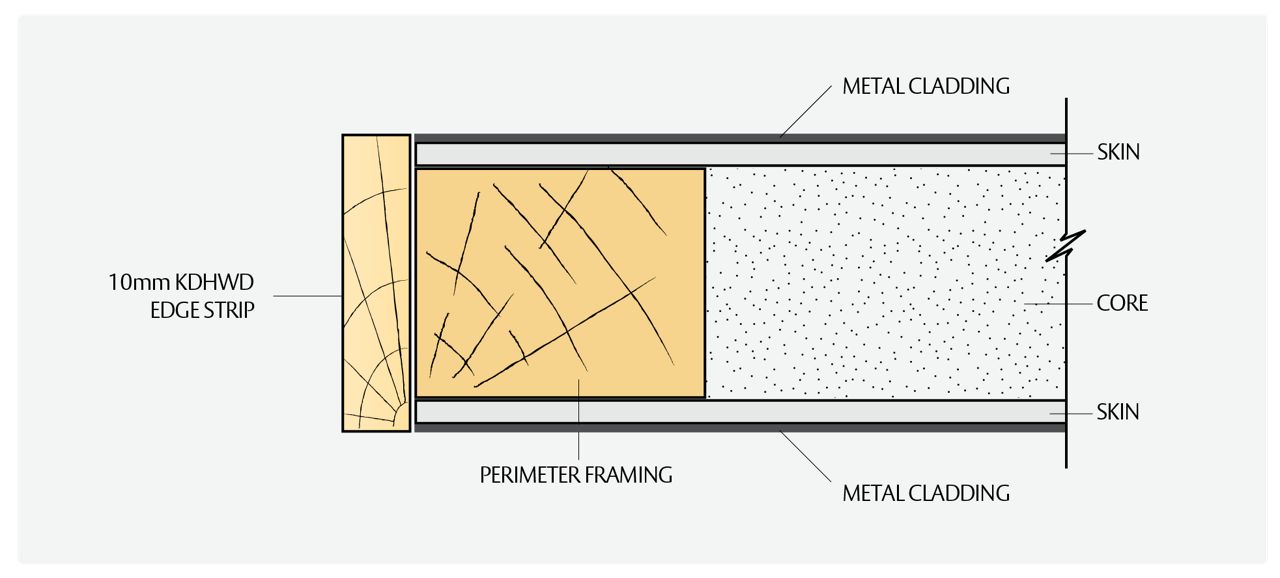

Edge Strip

A protective strip fitted to the door's edges to mitigate damage or degradation over time. Metal clad doors may be fitted with edge strips in many different configurations with or without capping.

Similar Products

Veneer Clad Doors

Interior doors doors crafted to your specification with an extensive selection of attractive veneers adhered to the door skin.Laminated Doors

Doors finished with a laminate for protective door face covering and a visually sleek finish. Laminates are a finished product that require no further preparation on-site.Radiation Door

Radiation Doors feature lead-lining in their core to contain the radiation emitted by X-ray devices in hospitals and healthcare facilities.Hygiene Door

Hygiene Doors are composed as a barrier against contaminants. Built to minimise the transmission of viruses and pathogenic bacteria between rooms.