Metro Tunnel Stations

Spence’s involvement was in service of client Cross Yarra Partnership as part of the Victoria’s Big Build initiative.

The application of our purpose-built doors spans Arden Station, Parkville Station, and Anzac Station. The breadth of Spence’s manufacturing capacity met the volume requirements along with the specialty purpose of each distinct door set.

The build was an enormous undertaking that spanned 4 years of project management. Hundreds of Spence door and frames can be found across each of the three stations. The result is an apt illustration of Spence’s extensive manufacture facilities going hand-in-hand with Spence’s project management, while keeping pace with construction phasing. The timeline of public facilities such as the Metro Tunnel features many moving parts. Informed by decades of public building experience, Spence is ready and able to deliver under expected and unexpected conditions alike.

A Platform for Success

Door sets for station platforms were specified with respect to the high-traffic and high visible exposure of these settings. Security measures were taken in the form of Solid Core door leaves built to prevent intrusion. This was an essential for high-risk areas like the on-platform Protective Service Officer (PSO) stations. Solid core construction also provided these doors a high level of insulation. The subsequent acoustic and climate control qualities suitably separated the platforms from all adjoining areas.

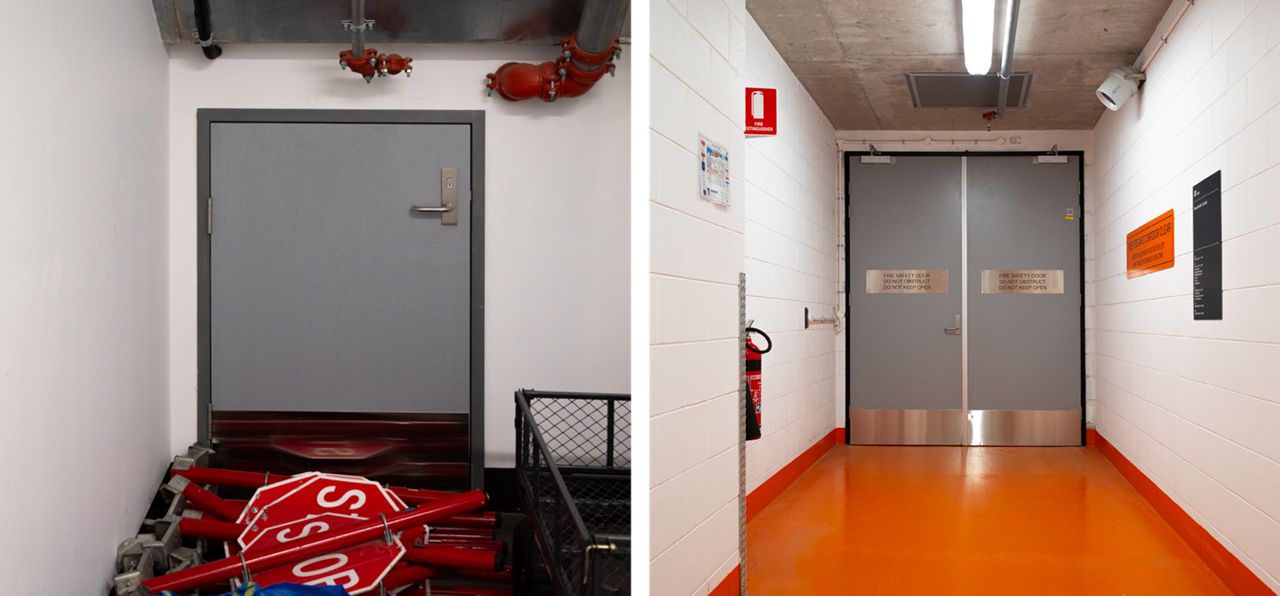

A mixture of door set configurations appear throughout the various platforms of all three stations. Meeting the specific purpose and wall opening specifications of each installation involved custom-sized doors of both single and pair swing construction. Although many doors greatly differed from another, a common thread was their protective properties. This is exemplified in the metal kick plates fitted to the lower section of most doors’ faces. Such protection accounted for the long-term visual and functional upkeep against degradation of people and objects knocking the doors.

Many on-platform doors also serviced the separation of fire compartments from platforms to connected areas. Fire-rated doors were manufactured to specification for up to two hours of fire resistance. Safeguarding all users in the event of a fire required the Spence team to maintain high scrutiny of manufacture and installation compliance with the National Construction Code (NCC) and relevant Australian Standards. In this same manner, hardware like Panic Bars were fitted in a number of instances to support safe passage from area to another. Permitting opening of latched doors with a single push motion, Spence’s doors were prepared with all necessary internal supports for the hardware.

A High Standard for Working Conditions

Staff areas required a unique set of hardware appropriate to working conditions. Ensuring a well-ventilated space was a key objective in this. A number of doors were fitted with dual ventilation grilles in support of the buildings’ HVAC systems. Cutouts for this hardware were completed during manufacture for ease of installation on-site. The resultant control of proper airflow between rooms is both a health & safety measure and a means of maximising the efficiency of heating & cooling systems. This is particularly important in bathroom spaces where there is otherwise an active risk of moisture build-up.

Acoustic attenuation between spaces was another primary objective in staff areas. Quiet working conditions amongst a bustling facility like a train station necessitated the fitting of acoustic seals on door sets. The ability for sound to pass through a door set is dependent on the various gaps for it to navigate. In these instances, the Pressed Metal Frames produced by Spence feature a space for a rubber seal to be adhered. The seal covers off the gap between door leaf and frame when closed. The largest present gap however is the space between the door leaf’s underside and the floor covering. Drop seals were fixed to the bottom of these doors’ faces to cover this gap and mitigate noise transfer.

Out-of-sight, Kept-in-mind

Back-of-house areas featured significant diversity in door set configurations. These areas and connecting hallways are home to heavy machinery and service facilities. This is where Spence’s adept experience in manufacturing variations was vital. Spacing for wall openings in these service areas worked around the complex architectural planning; resulting in some unusual sizing of wall openings. This is demonstrated in extremely short doors creating an opening in the confined space below staircases, to the oversized doors where large equipment needs to be transported.

Many service access points featured riser doors framed on all four sides. The non-standard engineering of these openings along with their custom dimensions were both factors incorporated into Spence’s door manufacture. All were fitted with Door Closers – and prepared accordingly in Spence’s factory – to ensure they maintain their closed position at all times when not in use.

Acoustic sealing in substations was another primary consideration in door construction. The machinery housed in these areas create noise pollution typical of industrial settings. Spence’s Acoustic Doors were built with a proprietary core designed for high-density. In the same manner as the staff areas, seals were fitted around and under the doors to close off all gaps where noise would typically pass through. These doors were altogether built to achieve the desired Rw rating of each opening in conjunction with the properties of the surrounding walls. Containing noise within these rooms assured that the atmosphere on-platform was not disrupted as well as maintaining a safe noise level for nearby staff.

Many door sets throughout the back-of-house areas also feature Vision Panels; doors were prepared with this in mind and fitted in Spence’s factory. The result was a direct eyeline between rooms for security and safety purposes whilst maintaining the door’s closed position for privacy and acoustic separation. This was applied to doors ranging Flush Panel, Fire-Rated and Acoustic-Rated purposes.

Shaping the Metro Tunnel

The Metro Tunnel is a major step forward in connecting Victorians. Ease of travel across the city and its surrounds is vital in supporting Melbourne’s continued growth. Involvement in such a momentous project via the supply of doors has been a valuable experience for Spence - gratifying in its significance and exciting in its scale. The tight timelines and door set variations together presented a challenge that our Manufacturing and Logistics team gladly met. This project has been a fitting demonstration of Spence’s capability to manufacture at scale with a handle on meeting compliance and communication.

Become our next study.

Related Products

2HR Fire-Rated Door Sets (Single)

Complete door sets for 2 hours of fire resistance featuring a single door leaf.Non Fire-Rated Acoustic Door Sets

Door sets for acoustic isolation between rooms that do not also require fire rating.Metal Clad Doors

Metal clad doors for high strength protection of the door leaf. Built for commercial and industrial conditions and sheltered outdoor application.- Door Frames

Fire-Rated Metal Frames

Specially designed fire-rated door frames that work in conjunction with fire-rated doors to create a complete fire-resistant barrier. - Door Feature

Ventilation Grille

A slatted grille fitted into a door face to manage airflow between spaces. - Door Feature

Vision Panel

A door face panel for a window to be fitted allowing vision through without opening the door.