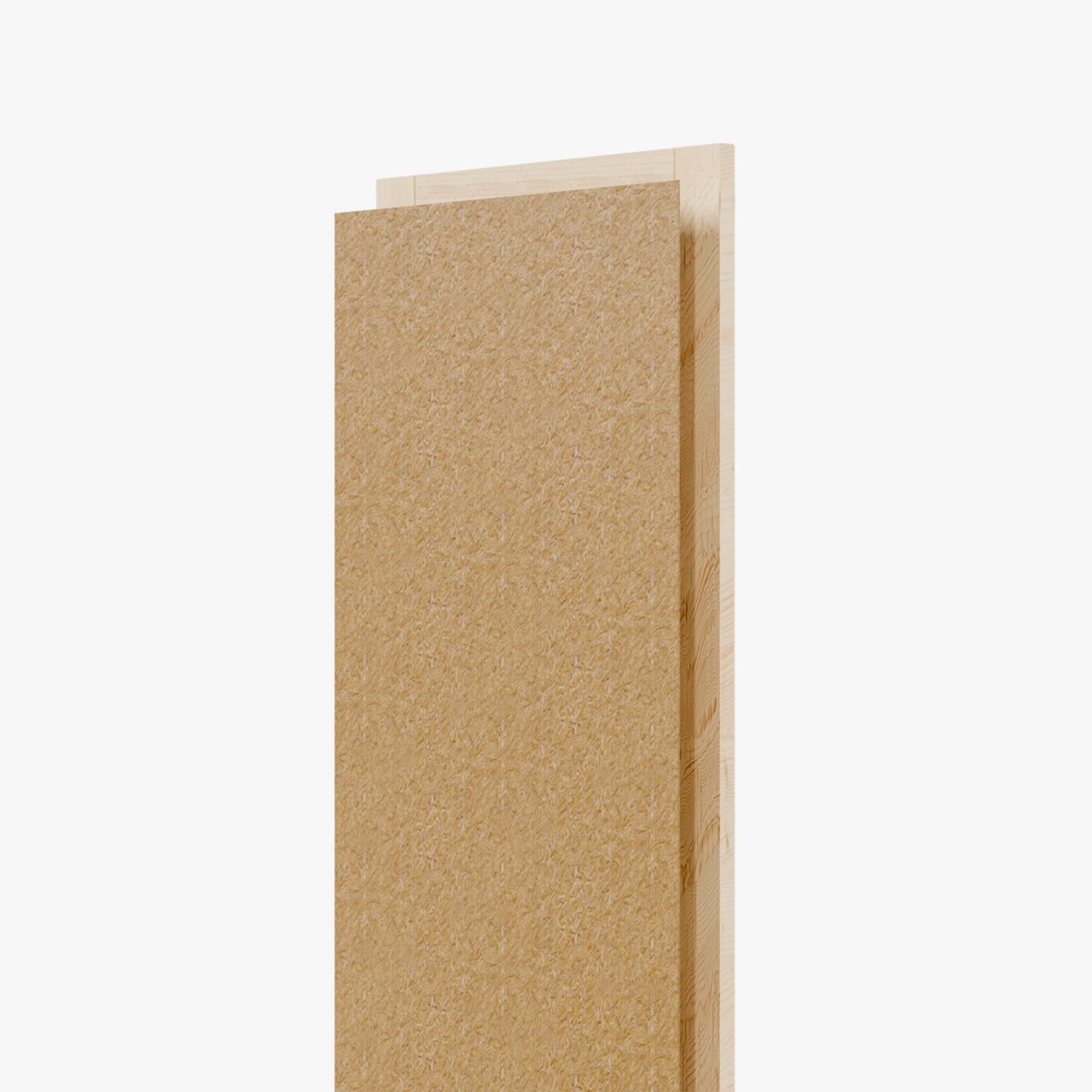

Semi-Solid Doors

Flush Panel Doors featuring a semi-solid core suited for a lightweight build and cost-efficient construction. The light door leaf weight is indebted to its honeycomb-mesh cellular core which places minimal stress on the frame to, in turn, minimise maintenance and extend the door set's life cycle. This is of particular importance for large doors where its weight would otherwise put the frame at risk of warping without fitting additional support hardware.

When to Specify Semi-Solid

The composition of a Semi-Solid Door is cost efficient relative to a Solid Core Door and so is suited to budget conscious projects. Such efficiency is appropriate for commercial settings where the bulk installation of doors are required to fitout a large building. If required doors vary in their height, width, configuration, or hardware to be fitted; this is addressed by Spence's specialist manufacture as all doors are made-to-order to specific project needs.

The lightweight build also makes for easier transportation and subsequent minimisation of damage risk in transit. Once on-site, the light construction is a benefit for ease of handling and installation thereby reducing the time and effort of labour.

Semi-Solid Doors are typically applied to common areas where the door is predominantly for passageway and visual privacy purposes. Conversely, a Solid Core is more suitable for properties including acoustic performance, entry door security, and temperature control between rooms. Additionally, a Solid Core is necessary for the fitting of door face accessories like Vision Panels and Ventilation Grilles.

Pick Your Profile

Spence Doors manufacture four profiles of Semi-Solid Doors that vary in the internal timber frame construction. This frame is made up of two vertical sections (stiles) and two horizontal sections (rails) which all door hardware will be fitted into. Each profile features a different width/depth to these timber sections to accommodate varying types and sizes of hardware to be fitted. This allows for the requisite space to install the likes of concealed hinges, door closers, and large door handles or locks.

35mm / 35mm Semi-Solid Profile

Featuring an internal frame with 35mm thick rails & 35mm thick stiles. Includes 600mm tall universal lockblocks. Suited to doors that will not have bulky hardware fitted.1 of 4

Lightweight

Light build makes for ease of door transport and installation.

Cost Efficient

Well suited to accommodate project budget requirements.

Frame Friendly

The lightweight body bares minimal stress on the frame and hardware.

Specifications

The material and dimensional properties of Spence's Semi-Solid Doors.

Models

The variants of Semi-Solid Doors manufactured by Spence Doors. Variations in the internal timber frame address different installation requirements like hardware fittings.

Skins

Options for the skins fitted to both faces of the door leaf. Choice of skin composition determines properties including moisture resistance and paint finish.

Extras

Internal Frame (RHS)

An internal metal frame to combat bowing in oversized doors. Recommended for doors exceeding 2400mm height or 1200mm width.

Mullion

A mullion framing component may be fitted to Flush Panel Door Sets for the fitting of a sidelight. This is an excellent means of letting natural light flow between rooms.

Edge Strips

A protectant measure against damage and degradation to the door leaf's edges. Particularly of use if the door is finished with a veneer or laminate as Edge Strips protect finish's edges from peeling.

Similar Products

- Door Feature

Internal Frame (RHS)

A metal frame fitted inside the door leaf to reinforce its structural strength. Veneer Clad Doors

Interior doors doors crafted to your specification with an extensive selection of attractive veneers adhered to the door skin.Solid Core Particleboard Doors

Flush Panel Doors featuring a solid particleboard core.Laminated Veneered Lumber (LVL) Doors

Flush Panel Doors featuring a solid Laminated Veneered Lumber (LVL) core.