Warp Resistant

The door's composition is designed to mitigate warping and shrinking.

Flush Panel Doors with a solid laminated veneered lumber (LVL) core. LVL is a high-strength engineered wood made by the bonding of thin pine wood veneers together under heat and pressure. This makes for a robust and high-density material appropriate for both indoor and outdoor application. The core is surrounding by a timber perimeter frame of 35mm stiles and rails. This frame is constructed from KD Hardwood or Finger Jointed Pine.

The LVL Advantage

Laminated Veneered Lumber hosts a number of beneficial properties including:

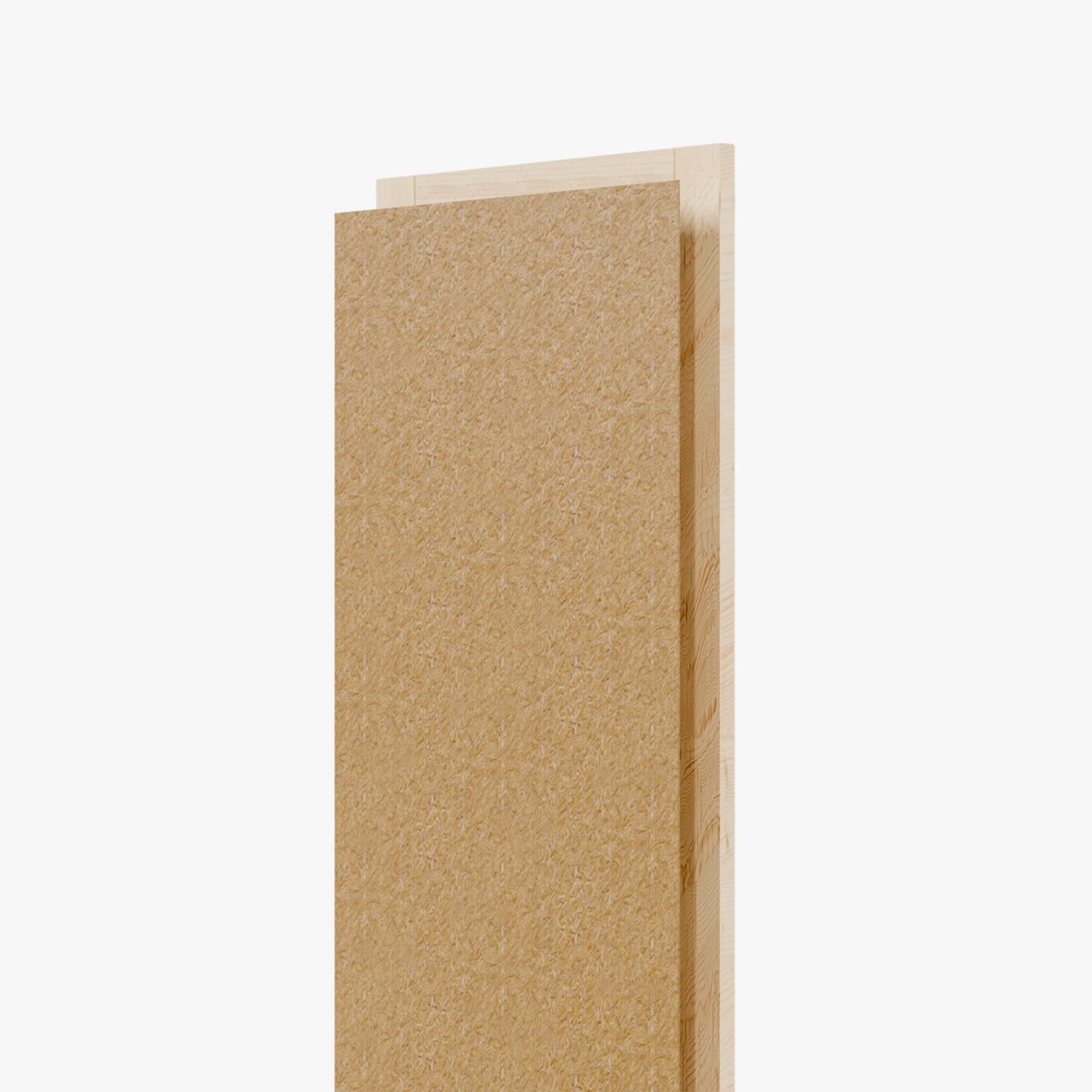

LVL Door Profile

A Flush Panel Door with a solid LVL core.The door's composition is designed to mitigate warping and shrinking.

Engineered for strength to hold form against the pressures of high traffic and changing conditions.

Light build makes for ease of door transport and installation.

The material and dimensional properties of Spence's Solid Core LVL Doors.

Core: Laminated Veneered Lumber (LVL)

Internal Frame: 35mm thick Finger Jointed Pine or KD Hardwood

Door Leaf Thickness: 35mm - 45mm

Skin Thickness: 3.6mm - 6mm (up to 9mm in oversized doors)

Standard Door Dimensions*: 2100mm - 2400mm Height / 720mm - 1200mm Width

Standard Oversized Door Dimensions*: 2401mm - 3600mm Height / 1201mm - 1500mm Width

Fire-Rated: No

Acoustic Rated: When fitted with appropriate seals.

* These are standard dimensions however all doors are made-to-order so you can contact the Spence team to discuss manufacture outside of these dimensions.

Options for the skins fitted to both faces of the door leaf. Choice of skin composition determines properties including moisture resistance and paint finish.

Door skin composed from Medium Density Fibreboard.

MDF is perfect for a premium look in settings where the door is an architectural design feature. This is on account of the uniform surface of the material and the resultant smooth paint finish. It is however not suitable to wet areas as particleboard splits and warps when exposed to moisture; advised for installation in common areas like living rooms, bedrooms, and entry doors, but not for the likes of bathrooms.

Variants:

Primed MDF - An optional extra to have the MDF skin primed during the manufacturing process. This priming layer makes for a consistent paint finish in applications where aesthetic is a priority. It also serves to save time on-site with the ability to jump straight to painting rather than priming doors and waiting for the primer to dry.

MDF XP - A construction of MDF engineered for a greater level of strength. Suited to application where impact, slamming, or high-traffic are risks and the maintenance of the door and its appearance are key.

Door skin composed from plywood veneers.

Ply is a moisture resistant suitable for application in wet areas like bathrooms. The material properties and build of Ply ensure it holds form under changing conditions of temperature and moisture exposure. Ply naturally has a rough grain texture and so is typically not chosen for premium architectural design settings.

Variants:

Marine-Grade Ply - A variant of plywood manufactured for high-moisture settings. The resin used to bond the material withstands extreme and/or consistent exposure to moisture so is suitable for very wet areas.

The premum door skin option composed from hardboard and tempered for greater durability.

Hardboard is a stiff wood product - the strongest material amongst skin options. This is suited to impact resistance in settings where physical damage is a risk or high-traffic is expected. Tempered Hardboard hosts a similar paint finish to MDF on account of its smooth surface and combines this with a moisture resistance similar to Ply making it suitable to wet areas.

An internal metal frame to combat bowing in oversized doors. Recommended for doors exceeding 2400mm height or 1200mm width.

A mullion framing component may be fitted to Flush Panel Door Sets for the fitting of a sidelight. This is an excellent means of letting natural light flow between rooms.

A protectant measure against damage and degradation to the door leaf's edges. Particularly of use if the door is finished with a veneer or laminate as Edge Strips protect finish's edges from peeling.

A window fitted to the door face for visibility between rooms. Options available for glass finish and thickness.

A grille fitted into the door's face to allow for airflow between rooms. This is a support of a building's HVAC systems, ensuring appropriate airflow and minimising air conditioning costs.