Alexandra Gardens Public Toilets

Located in the heartland of Melbourne, access and maintenance of the public facility is of high importance. Considerations towards the doors’ heavy usage and disability access were both accounted for in the specification and manufacturing processes.

Spence Doors & Record Doors worked together to supply the specialty doorsets required of the project. Both ASSA ABLOY businesses’ specialist areas were required to together deliver doorsets that were durable, secure, and accessibility compliant.

Spence manufactured a series of Metal Clad Doors for the build custom to the wall openings and Record Doors’ accompanying hardware. Solid Core door internals addressed security against intrusion and rigidity against bowing. Particleboard was elected as a suitable core material provided its balance of strength and thermal properties. Spence’s manufacturing capacity permitted the bespoke build of all doors at their 50mm leaf thickness.

All doors were well protected for their outdoor setting and the environmental conditions to which they are subject. This protection came in the form of cladding and capping to completely encase the door leaves against the elements. This included a Colorbond cladding extending across both sides of the door faces. Capping in a matching finish was applied to all four sides of the doors, a critical component in disallowing moisture from entering the door’s structure.

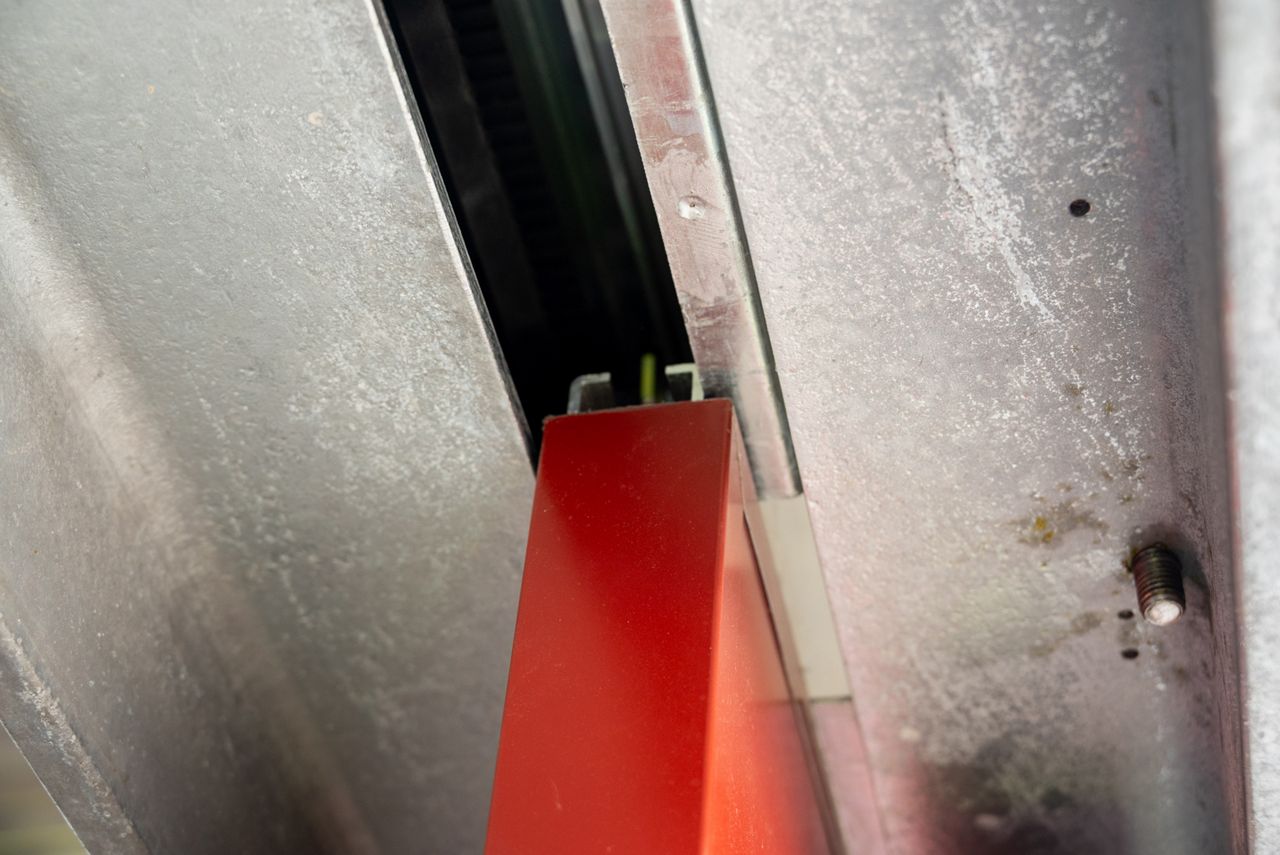

All doors were hung with Record Doors’ STA 20 Sliding Door hardware. The automated opening/closing mechanism made for easy and Australian Standard compliant access to all entryways. As part of this fitting, each door required an underside cutout for sliding hardware. Spence completed these hardware cutouts during manufacture; the CNC machining of these cutouts were made precise to the hardware model being fitted.

Spence National Projects Manager David Weymouth said of the project “manufacture and communication alongside Record was a smooth process which was crucial given the doors for this were quite custom.” Record Business Development Manager Beau Bruce shared this sentiment saying “It’s always rewarding to see how well our Record STA 20 performs in custom applications like this. Collaborating with Spence Doors made the process seamless — a great team effort with an excellent end result.”

This project was a terrific collaboration and made for a high-quality result. It is particularly rewarding to see Spence’s work at home in an iconic Melbourne location. The project is an apt demonstration of Spence’s custom production capabilities.

Become our next study.

Related Products

Metal Clad Doors

Metal clad doors for high strength protection of the door leaf. Built for commercial and industrial conditions and sheltered outdoor application.Solid Core Particleboard Doors

Flush Panel Doors featuring a solid particleboard core.