Non Fire-Rated Metal Frames

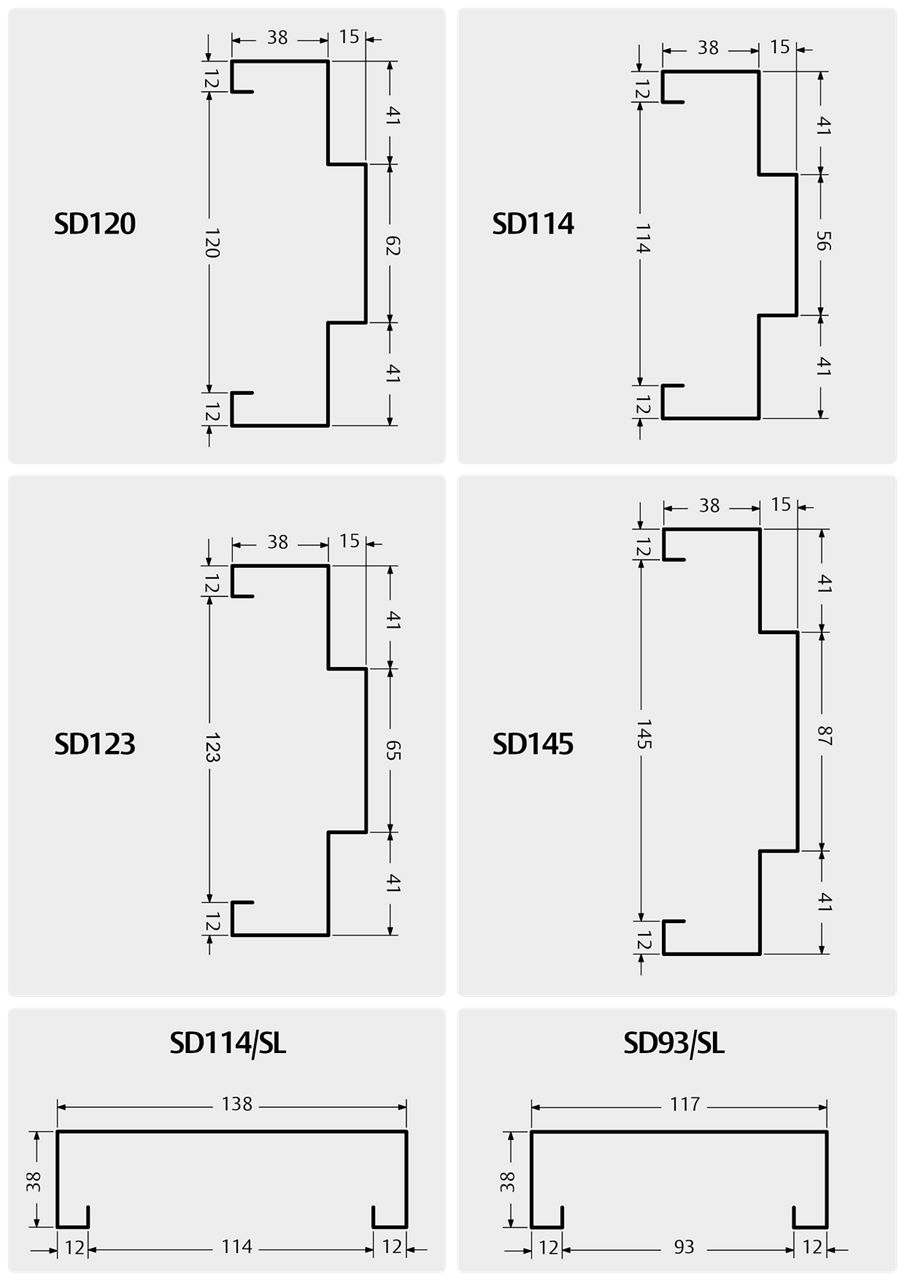

This collection of frames is suitable for applications where fire resistance is not required. Versatile by design as each frame profile is available in various sizes to fit different wall types. A wide range of profiles offer a breadth of options in installation methods and accommodation to varying wall openings and door types.

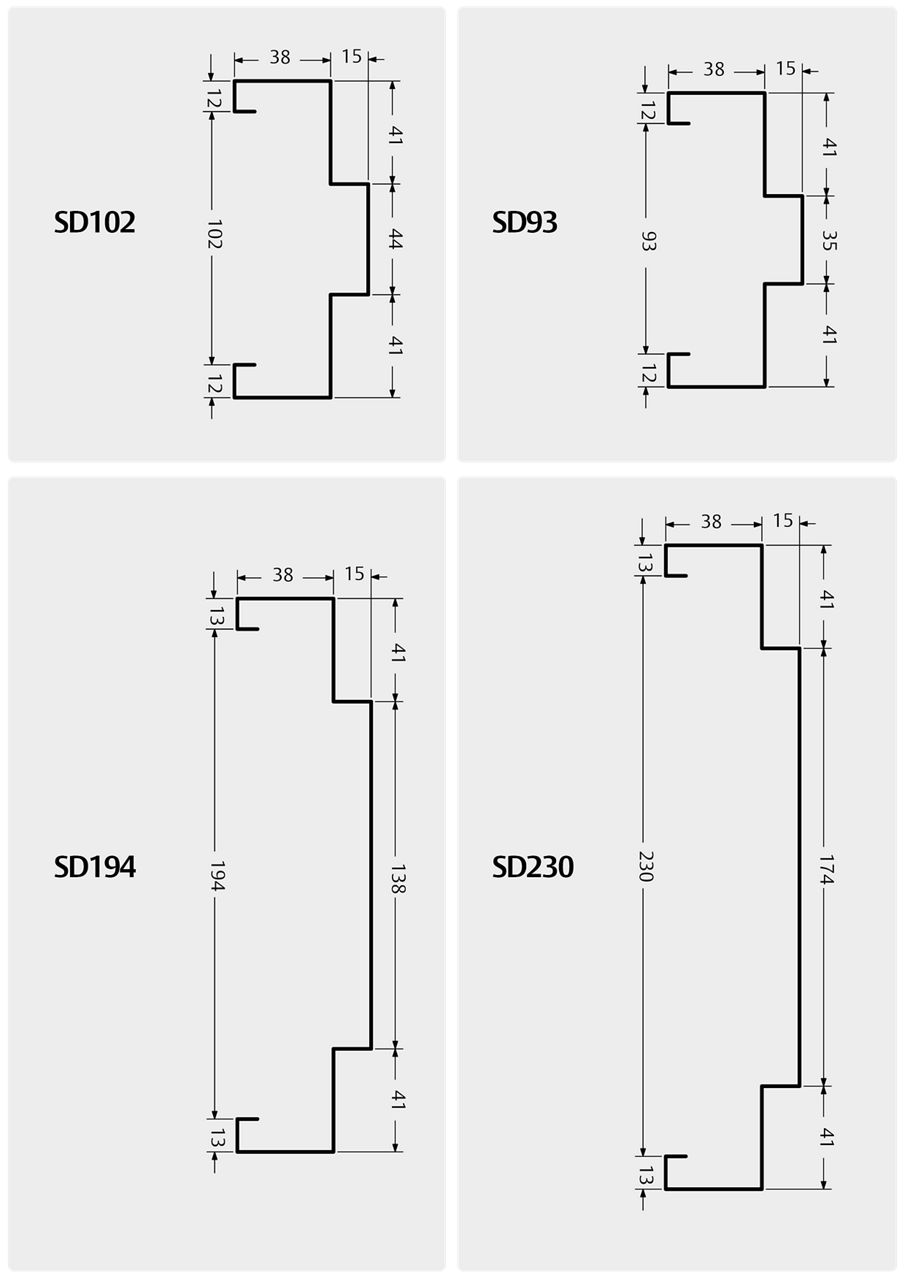

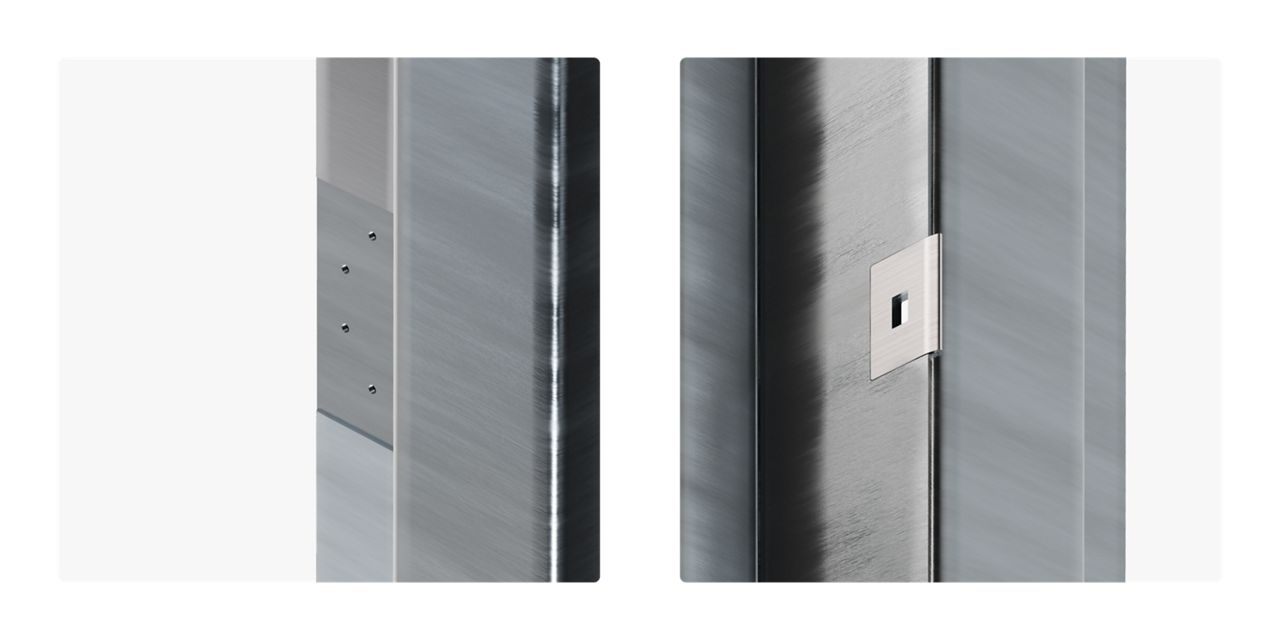

Metal frames are supplied as assembled systems for easy on-site fitting or retrofitting. Available in a range of finishes including Zincanneal, Galvanized Steel and Stainless Steel.

Preparation

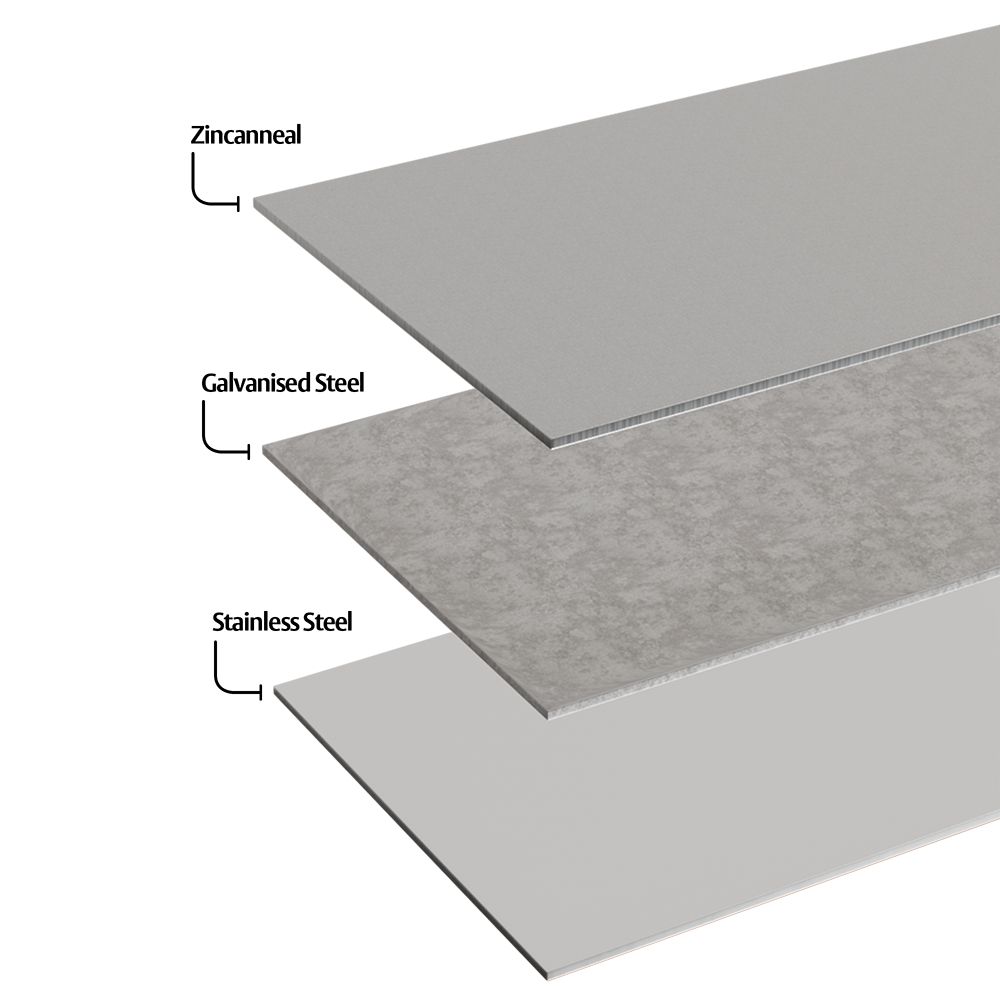

All hinge and latch striker preparations are completed prior to delivery; Spence Doors has an exhaustive database of hardware that can be profiled into the frame. Additional preparations such as cutouts for Door Closers can also be specified and prepared during manufacture. By standard, all Pressed Metal Frames are welded and assembled for ease of installation. Knock-down frames are also available to accommodate project needs and transportation purposes.

All frames also have a selection of coatings available for specilaist needs and maintenance of the frame over an extended period of time. Zinc-Coating, Etch Priming, and Hot-Dipped Galvanisec coating offer varying levels of additional protection.

Installation

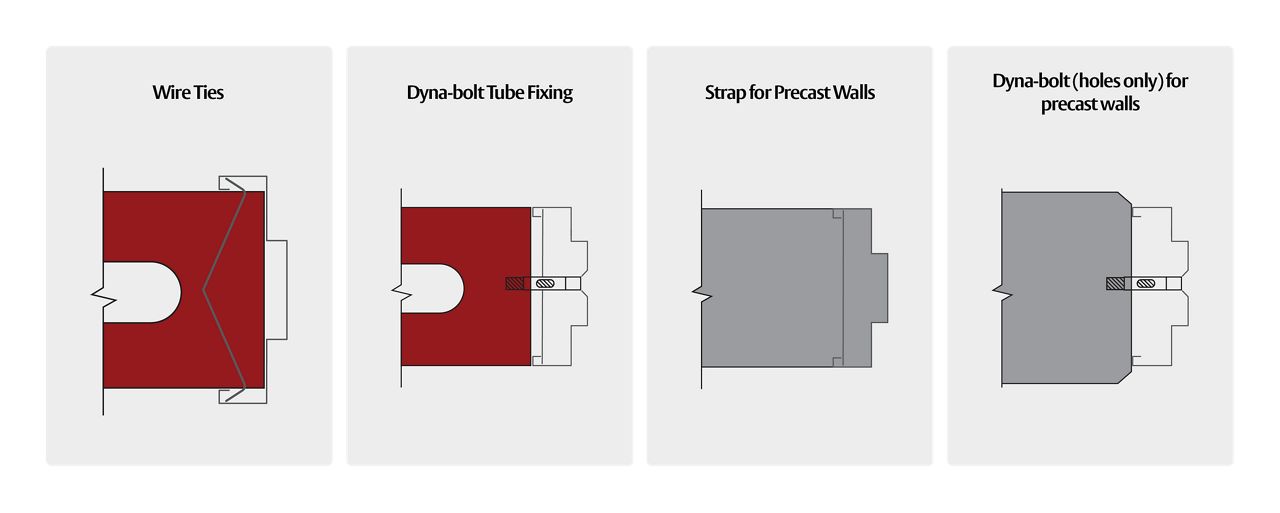

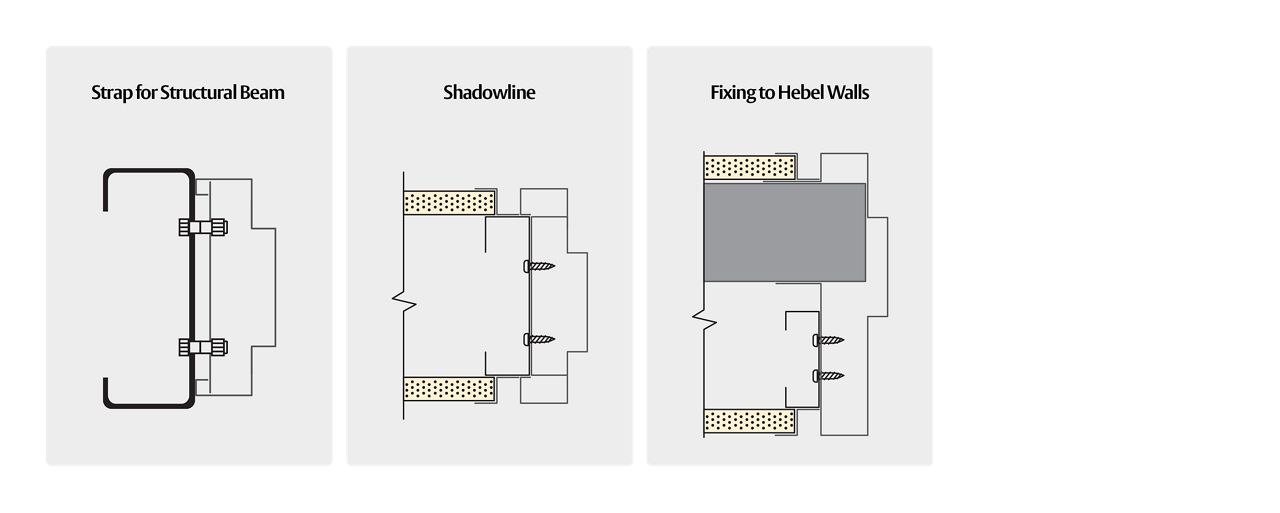

Spence Doors' Pressed Metal Frames are designed for installation in a variety of wall types. Capable of being installed in standard, masonry, hebel, structural and more wall types. See all installation methods below.

Zincanneal Door Frame

1 of 3

Pre-Assembled

Frame comes pre-assembled for simple fitting on site.

Zinc Coated

Steel surface is zinc coated for protection of the steel.

Options

A wide selection of options are available to accommodate specific needs.

Specifications

Installation

Built for Purpose

Optional Extras

Similar Products

- Door Frames

Fire-Rated Metal Frames

Specially designed fire-rated door frames that work in conjunction with fire-rated doors to create a complete fire-resistant barrier. - Door Frames

Timber Door Frames

Timber door frames designed for quality and durability. A reliable choice for both residential and commercial applications. - Door Frames

Metal Cavity Units

Custom-made steel cavity units built for durability in high-traffic doorways and the rigours of residential, commercial, and industrial spaces. - Door Frames

Timber Cavity Units

Custom-made timber cavity units constructed from high-grade Australian timber for sturdy build and premium finish.