How Fire Doors are Tested in the Lab

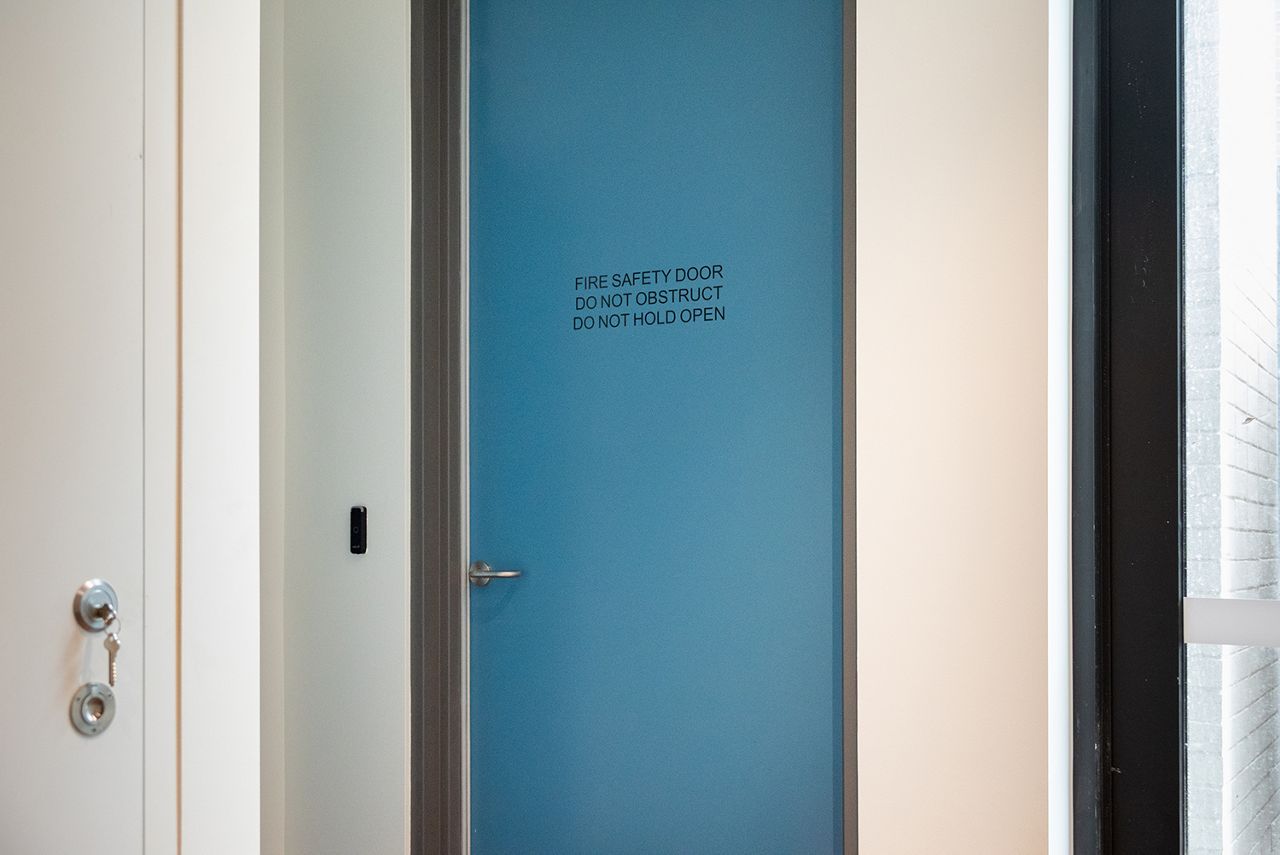

Fire Door Tags

A tested and certified Fire Door is fitted with tags that verify its fire resistance.

In order for a door to be certified as 'fire rated' it must be rigorously tested. The laboratory that holds the test and the manner in which they complete the test are subject to strict procedures.

Held by an Accredited Organisation

The National Association of Testing Authorities (NATA) has a list of accredited organisations who represent a high standard for testing accuracy and safety procedures. Laboratories that hold this accreditation may complete a fire door test that will prove the doorset’s fire-protection in accordance with AS 1530.4:2014. Manufacturers send their products to these laboratories to have them tested in varying configurations in order for them to be specified in Australian commercial buildings.

The Test Process

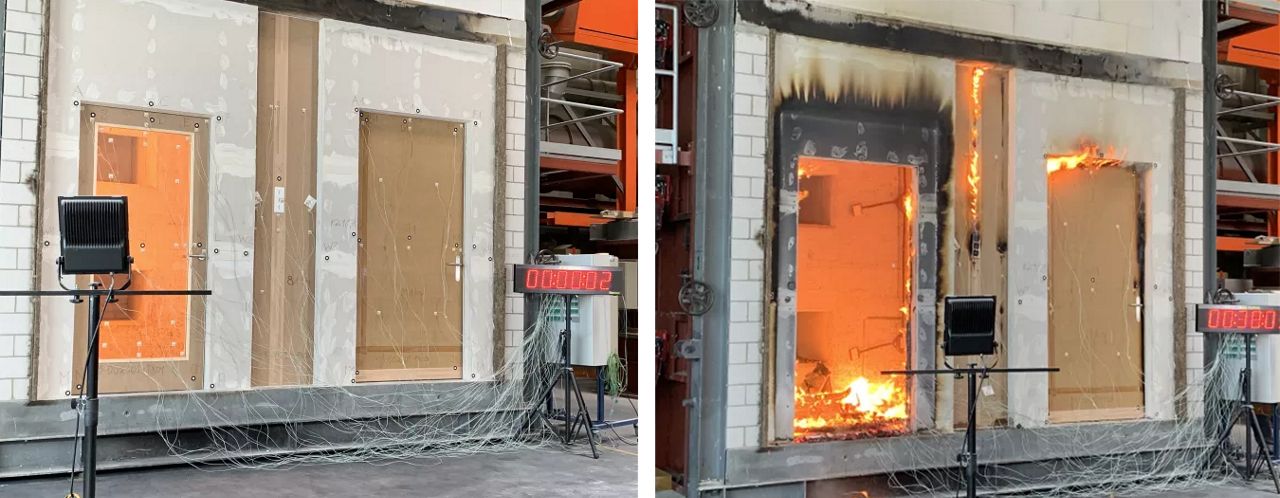

The testing of a fire doorset is designed to mimic a real-life fire situation in a building and determine how long the doorset can withstand direct exposure to fire. CSIRO is one such company that is NATA accredited; they describe the test process as ‘utilising a 3000 x 3000 mm wall furnace for walls and other elements and features fitted within walls’.

Effectively, the complete doorset (door leaf, door frame, door hardware) is installed into a wall inside a furnace. Within this furnace, the door is exposed to an open fire on one side of the wall until the fire escapes through to the opposite side. Sensors are fitted to a number of points on the door face and frame on the non-exposed side. These sensors read the temperature on the non-exposed side to gauge how much heat is being transferred through the doorset.

Visual degradation is also noted by inspectors handling the test as any warping or bowing in the door leaf can then be visually identified. The burning process on the furnace-side is also captured on video for a record of both sides to inform the test’s results.

The fire-exposure continues until the fire penetrates the doorset through to the opposite side. The timer is stopped at this point having recorded the time period over which the door functioned as a fire-resistant barrier. This time is rounded down to the closest 30-minute increment that the door passed – 30 minutes, 60 minutes, 90 minutes, 120 minutes and so on. This transcribes to the doorset’s certified Fire Resistance Level (FRL).

The Assessment Report

Once testing is complete, an assessment report is published by the laboratory. This outlines how the door performed under the fire-exposed test conditions with a comprehensive detailing of all data collected by the test. A final ‘opinion’ or ‘assessment’ is put forth by the laboratory concluding whether the doorset has satisfied all relevant requirements in the Australian National Construction Code (NCC).

As per Australian standards, minor variations to the tested doorset can be assessed by the laboratory for certification without the need for a complete re-test.

The assessment provided by the laboratory has a set validity period before expiring. This is typically a 5-year period but ultimately is dependent on the laboratory’s judgement. As such, a doorset’s certification as a compliant fire-resistant barrier is time sensitive in line with Australian Standards continually updating for the greatest safety of building occupants.

The Fire-Tested Spence Range

Spence offers a wide range of doorsets that have been certified by this testing process. Years worth of testing has built a database of different door configurations that are certified for fire-protection. The result is one of the largest sets of hardware in the Australian market tested for use on fire doors. This gives spec flexibility as there are more options to choose from when pairing the preferred hardware with a fire door. Additionally, Spence fire-rated doorsets have been tested for variations in function, leaf number, frame type, door skin, cladding, accessories, wall type, and frame extensions. Explore the full range of Fire-Rated Doors here.